Overview

Tensile Fabric Structure forms a part of a unique technology that gives architects, designers, and engineers to create exciting structures and experiment with the shape. These tensile structures are visually quite stimulating, and they are economically competitive and environmentally reasonable.

The materials used in these types of shade structures are relatively lightweight, and they are quite efficient in the long run. Also, they provide the cover of the building and come up with a basic architectural form.

In general, it is seen that the conventional structures depend on the stiffness to carry loads and to attain stability.

On the other hand, the tensile fabric structure is constructed using shear stiffness elements, and they use the internal tensile forces to carry the loads. These kinds of shade structures can be quite complicated to design as they possess highly non-linear behavior. Also, when the design starts, then the shape is also not known.

Once the tensioned fabric starts to deform, then it potentially increases the capacity to carry the load. The applied load to self–weight ratio is very well maintained as compared to concrete and steel structures of the same load.

Why are the Tensile Structures shape like this?

It is known that flat and large fabric pieces are relatively low in terms of resisting the loads. For instance, take a ball and attach it to four strings. Try to lift the two opposite columns up and, on the other hand lowering the other two lines.

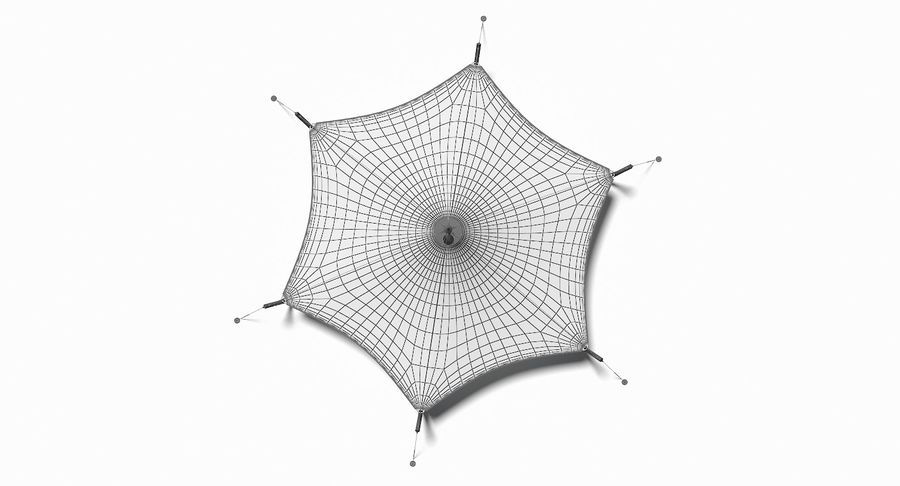

You will notice that the ball is locked in the space. You can apply the same principle to fabric membrane, and you will come across an anticlastic double curvature surface. It may sound quite impressive, but the fact is that it is emerging from the three pre-defined fabric shapes such as a cone, hyper, and the barrel.

What is the future scope of the membrane structure?

Much technological advancement is taking place in membrane structures, although some problems still need to be addressed. It is undoubtedly hoped that some methods would be developed to make the membranes last for a long time. It is also known that if technology increases, then the quality of the material would also increase.

Hence, to improve the innovative work, safety, and design, it is essential that a lot more techniques are being developed, and thus a lot more researches need to be carried out. Also, the publication of the standard code should be done based on the country.

What are the materials that are used for coating the Tensile Fabric Structures?

There are four commonly used materials that are used for coating the tensile fabric structure. It has been mentioned below in brief:-

- PVC coated polyester fabric

PVC is the acronym used for Polyvinyl chloride, and it is applied in the form of paste on the fabric. It assists in cleaning, and it helps in enhancing the surface aspects. Besides this, it helps in improving the yarn thermal properties. Different substances are applied for fire resistance, such as phosphates, phthalates, or ester as a secondary coat of plasticizes.

Also, PVC is used for light stability and imparting color. The PVC coat is used with stabilizing molecules to achieve oxidation, thermal, and UV protection.

- PTFE coated glass fabrics

PTFE is the acronym used for Poly tetra fluoro ethylene. This coating material is quite common, and it is widely used as it is backed with a lot of outstanding and multipurpose properties. This has been made possible because of the tetrafluoroethylene monomers chain arrangement.

It is also an excellent thermal insulator as it can easily resist high thermal temperatures, and it also has a very low coefficient of thermal conductivity. It is also quite resistive against abrasion and corrosive substances such as sulphuric acid and hydrochloric acid.

- Silicone coated glass fabrics

Silicone macromolecules are cross-linked to obtain the silicone coating. The silicone chain is used on the yarn, such as a protective coating is provided. One of the significant advantages of silicon is that the molecules’ chain can be combined with various chemicals to obtain the layer having a specific property as per the structure’s requirement.

For instance, Silicone substrates are combined with glass, such as a covalent hydrophobic film coating is formed.

- ETFE foils

ETFE is the acronym used for Ethylene Tetra Fluoro-Ethylene. It is a copolymer of tetra Fluoro-Ethylene and ethylene, and they have a very high melting point, i.e., between 250°C to 270°C. ETFE foils have a transparency advantage as compared to the other materials. It allows for the transmission of incident light up to 90%. Also, it helps to distribute stress.

What is the design process of the Tensile Fabric Structures?

The design process of the Tensile Fabric Structure is divided into three types such as:-

- Form-Finding

Form-finding is an iterative process in which the designer finds the best possible shape that a membrane can adopt.

2. Static and Dynamic Equilibrium

For structural designing, it is essential to look out for different kinds of load combinations. Further, the analysis is done to find the deflection.

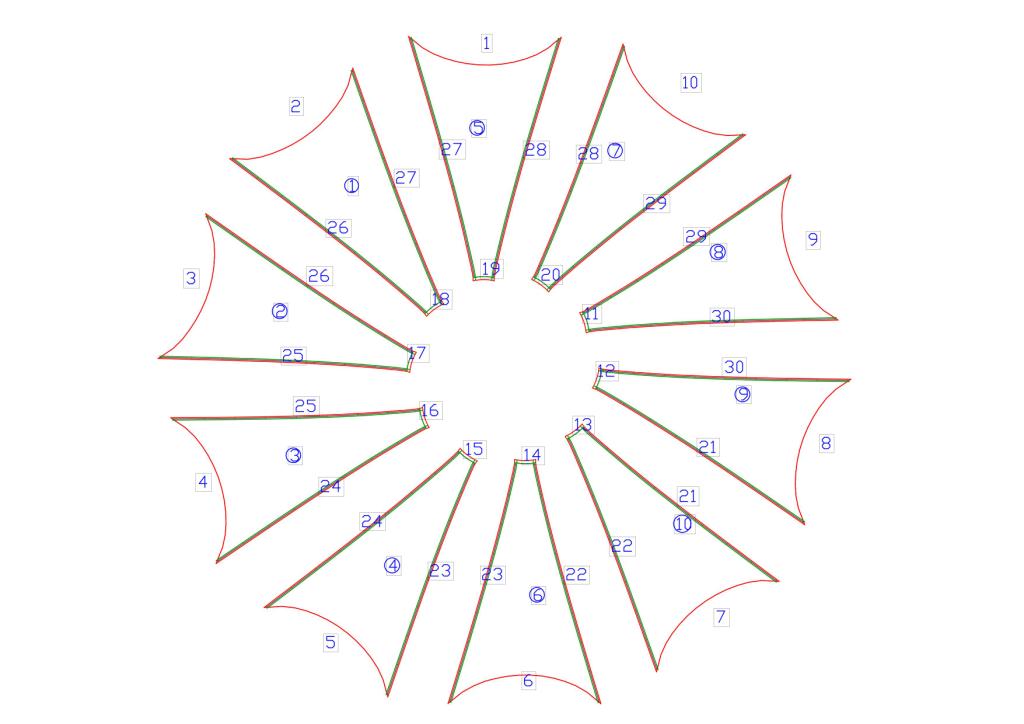

3. Patterning

It is known to be a process in which the 3D membrane, which is pre-stressed, is transferred into a pattern of 2D for the structural purpose.

Conclusions

Tensile Fabric Structures have many benefits associated with it, such as durability, simple construction, heat controlling capability, and sunlight controlling capability, to name a few. It is observed that the membrane shape is dependent on the initial force and not on the property or type of the fabric.